Tel: +86-10-8890 9291

MP: +86-13901376361

WhatsApp: +86-13901376361

Email: info@djm-bj.com leegang@djm-bj.com

Web: www.djm-bj.com

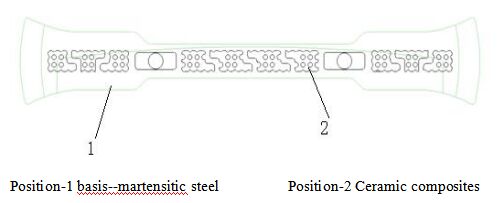

While the material in the scrapper channel moves, the internal friction in the material is generated by the pressure against scrapper chain and its own gravity, which will keep the material steady. This friction is greater than the outside one as the material slide in the channel, so the material is transported continuously as a whole. The scrapper flight bar should be strong, stiff, wear resistant and corrosion resistant, because it will bear a lot of force such as tension, pressure, bending, impact, friction and corrosion during the transporting. The scrapper chain move together with material in the scrapper channel, so both resistance and abrasion is great. The flat bar, made of 16Mn(or 40 Cr, 42CrMo), is the bear carrier and connected vertical to the chain. During operation, the flight bar will bear great resistance, dynamic load and static load, so the flight bar should be strong, stiff and wear resistant.

Picture -1 external view of flight bar

Tel: +86-10-8890 9291

MP: +86-13901376361

WhatsApp: +86-13901376361

Email: info@djm-bj.com leegang@djm-bj.com

Web: www.djm-bj.com