Vacuum pressure casting

Introduct:

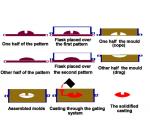

Vacuum pressure casting (VPC) uses gas pressure and a vacuum to improve the quality of the casting and minimize porosity. Typically VPC casting machines consist of an upper and a lower chamber. The upper chamber or melting chamber housing the crucible, and the lower casting chamber housing the investment mould. Both chambers are connected via a small hole containing a stopper. A vacuum is pulled in the lower chamber, while pressure is applied in the upper, and then the stopper is removed. This creates the greatest pressure differential to fill the molds.[14]